Cyclic Olefin Copolymers Lens for Terahertz Application

terahertz lens; hot compression molding; Topas COC; focal length characteristics

Abstract

The refractive index and absorption features of a novel polymer-cyclic olefin copolymers (trade names Topas COC) were studied in 0.1-3 THz band. With Solid Works soft ware, a comm on double-convex spherical lens of 100 mm focal length with effective aperture of 1.75 inches w as designed, and then a set of mold for manufacturing the lens w as designed. By hot compression molding, the Topas COC terahertz lens was fabricated, and the effects of heating temperature and time on the lens surface morphology was analyzed. The effects of the wavelength, thickness, radius of curvature and refractive index on focal length of the lens in the terahertz wavelength of 150 μm,300 μm and 600 μm was simulated and analyzed by using Zemax software. Studies have show n that the lens made by this method has surface smooth, high accuracy and defect-free structure, so the performance is very superior and meets linear and com pact requirements of the terahertz system, and plays the role of collimating and focusing in the visible region and terahertz band.

0 Introduction

Terahertz radiation usually refers to electromagnetic radiation with a frequency between 0.1 and 10 THz (wavelength between 30 μm and 3 mm), and its wavelength range is between microwave and far-infrared light. Its long wavelength band is similar to submillimeter waves. Coincidence, its development mainly depends on electronic technology; short-wavelength and infrared overlap, development mainly depends on photonics technology, the position of THz wave is just in the transition zone from macroscopic classical theory to microscopic quantum theory.

In almost all terahertz systems, lenses are required for collimation and focusing to meet the requirements of system linearity and compactness.

At present, the lenses used in the terahertz system can be divided into two categories according to the types of manufacturing materials. One is a high-resistance single-crystal silicon lens, and the other is a plastic lens. Plastic terahertz lenses are mainly made of high-density polyethylene (HDPE), polytetrafluoroethylene (PTFE), and Picarin; recently, it has also been reported that Zeonex plastics are used to manufacture terahertz lenses.

In this paper, a new type of polymer material, Cyclic Olefin Copolmer, with the trade name of Topas COC, is used to manufacture terahertz lenses. Compared with high-density polyethylene (HDPE) and polytetrafluoroethylene (PTFE) materials, Topas COC has high transparency in the visible light region; compared with the most commonly used optical polymer polymethyl methacrylate (PMMA), Topas COC has lower loss and negligible dispersion in the terahertz band. Therefore, the lenses made with Topas COC are superior to the existing HDPE and PTFE terahertz lenses for focusing and collimating terahertz systems; compared with terahertz lenses made of inorganic materials, such as high resistance Monocrystalline silicon hemispherical and crescent lenses, due to the low refractive index of Topas COC, have low reflection loss at the electrical interface and can maintain a good overlap between the free space mode and the guided mode.

At present, Lo and Leonhardt in Denmark have made aspheric terahertz lenses with polyethylene, which greatly improves the coupling efficiency of light. At the same time, there are also a small amount of Topas COC used in terahertz lenses. Research reports in Denmark and Canada and other countries Some people have started research in this area, but there is no report on the research on terahertz lens fabrication technology in my country.

Today’s polymer terahertz lenses are mostly made of rods that are turned or milled and then polished.

When the lens structure is relatively complex, this manufacturing method is time-consuming, difficult to operate and wastes a lot of materials.

In this study, the THz lens was fabricated by hot extrusion molding, and a special mold was designed according to the required lens parameters.

The manufacturing method in this paper is simple, low in cost, does not require particularly expensive equipment, and the manufactured lens has high smoothness, can be used directly without polishing, and is suitable for large-scale manufacturing.

1 Topas COC Material Properties

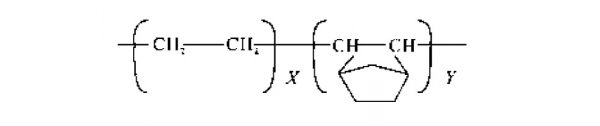

Topas COC is a cycloolefin copolymer obtained by copolymerizing bicycloheptene (norbornene) monomer and ethylene monomer under the action of metallocene catalyst. Different from crystalline polyolefins represented by polyethylene (PE) and polypropylene (PP), Topas COC is an amorphous and transparent copolymer with a cyclic olefin structure. Figure 1 is a schematic diagram of its molecular structure.

Fig.1 Topas COC schematic diagram of moleaular structure

It has good performance in many important indicators of optical materials, such as: high light transmittance covering the full spectrum, low birefringence coefficient, extremely low water absorption (PMMA, 1/10 of PC) and high Abbe number At the same time, it has many advantages such as good heat resistance, low thermal expansion coefficient, stable chemical properties, acid and alkali resistance and excellent mechanical properties.

The glass transition temperature of Topas was measured experimentally: 115.13°C.

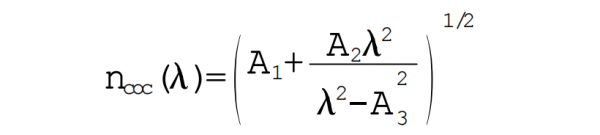

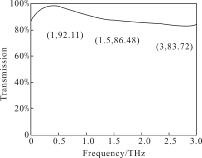

The relationship between the refractive index n∞ (λ) of Topas and the wavelength λ can be expressed by the Sellmeier formula:

In the formula: A1, A2, and A3 are fitting parameters.

In this paper, the terahertz time domain system (TDS) is used to measure the refractive index of Topas. Figure 2 shows the relationship between the refractive index of Topas and the frequency.

Fig 2 Refractive index n for slab pressed from micropowders Topas measured by THz TDS

It can be seen that the refractive index of Topas is stable between 1.530 and 1.534 in the range of 0.1~2THz, while the refractive index of Topas changes greatly in the range of 2~3THz, so the dispersion is also relatively large. The refractive index of the material at 1THz is 1.53257.

Therefore, it can be considered that the refractive index of Topas in the terahertz band (0.1~2THz) is approximately a constant 1.53.

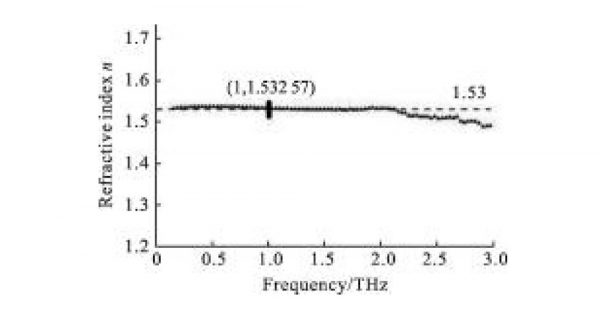

In this paper, the light intensity transmittance of the Topas sheet with a thickness of 2mm in the frequency range of 0.1~3THz was measured, as shown in Figure 3.

Fig.3 Transmittance of the terahertz frequency spectrum of the 2mm Topas slab

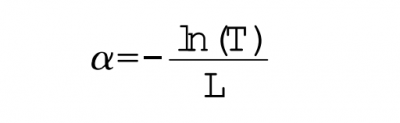

The relationship between the transmittance and absorption coefficient of Topas is:

In the formula:

α is the absorption coefficient;

T is the sample transmittance;

L is the thickness of the sample.

Figure 3 shows the transmittance of Topas at 0.1~3THz.

When the frequency F=1THz, T=0.921; when F=2THz, T=0.858;

When F=3THz, T=0.837;

It can be seen that within 0.1~3THz, the transmittance T>0.837;

Within 0.1~2THz, the transmittance T>0.765;

Therefore, within 0.1~1THz, the transmittance of Topas is as high as 90% or more. Especially in the vicinity of 0.4 terahertz, the transmittance is as high as 95% or more.

2 Lens Making

2.1 Lens Design

Terahertz lenses are distinguished by geometric shapes, mainly including plano-convex spherical lenses, plano-convex aspheric lenses, biconvex spherical lenses and aspheric lenses.

Because biconvex spherical lenses are most commonly used in terahertz time-domain systems and imagers, this paper takes the design of Topas biconvex spherical lenses as an example to study the manufacturing process of Topas lenses.

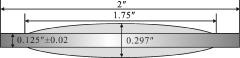

The designed lens diameter is 2inch (1inch=2.54cm), the effective diameter is 1.75inch, and the effective focal length is 100mm. The structure diagram of the lens is shown in Figure 4.

Fig.4 Model of lens

It is known from the results in Fig. 2 that the refractive index n of Topas is approximately 1.53 in the terahertz band range of frequency 0.1~2THz, and the refractive index of Topas is 1.53257 at 1THz.

In this paper, the structure of the lens is optimized by the Zemax software simulation, and the radius of curvature of the lens is calculated, as shown in Table 1.

Tab.1 Simulated and optimized structure parameters of the lens by Zemax

| wdt_ID | Surf: type | Radius | Thickness | Glass | Semi-diameter | Conic |

|---|---|---|---|---|---|---|

| 1 | OBJ Standard | Infinity | Infinity | - | 0 | 0 |

| 2 | 1* Standard | 100.69 V | 7.51000 | 1.53, 56.4 | 22.22500 U | 0 |

| 3 | * Standard | -100.69 P | 100.484 | - | 22.22500 P | 0 |

| 4 | IMA Standard | Infinity | - | - | 3.304250 | 0 |

The effective focal length of the lens is 100mm, and the radius of curvature is approximately 100.96mm. Considering the 0.6% molding shrinkage rate of Topas material, in order to meet the design requirements, the parameters such as the thickness, radius of curvature and effective aperture of the lens will be 7.55mm, 10157mm, and 44.72mm, respectively, and the focal length of the system will become 100.61mm, which increases the 0.61mm (0.61%), it can be deduced that the molding shrinkage will have a small effect on the focal length of the lens.

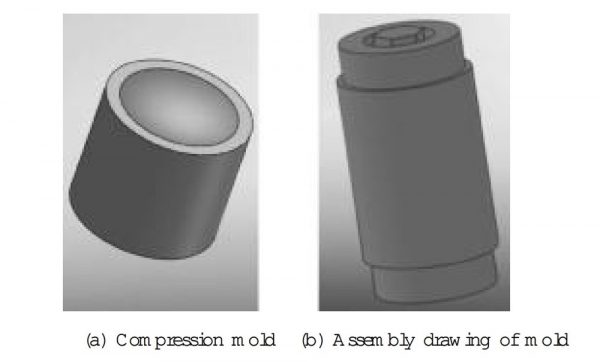

2.2 Mold Design

In this paper, the Topas terahertz lens is fabricated by thermocompression molding. This method is simple, the mold is easy to process and the cost is low.

Since the surface shape and surface finish of the lens used in the experiment must meet the requirements of high optical level, the surface shape accuracy and surface finish of the mold are extremely required, reaching about 10 grades (Ra0.2μm). The mold core is made of 45# carbon steel, chrome-plated on the surface, and micro-finished, as shown in Figure 5(a).

At the same time, a 500W electric heating sleeve is placed on the mold jacket to heat the mold; finally, in order to detect the mold temperature, a thermocouple temperature sensor should be sandwiched between the mold and the digital display heating sleeve. At this point, the design of the core part of the mold is completed, as shown in Figure 5 (b).

Fig.5 Structure of mold

3 Manufacture of lenses

3.1 Manufacturing process

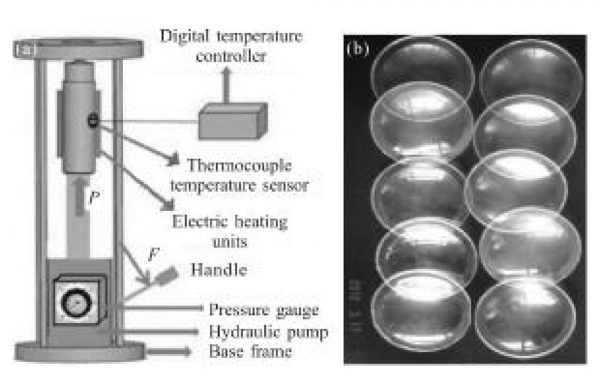

Using a hydraulic jack, pressure gauge, mold, electric heating sleeve, thermocouple sensor, numerical control heater and other components, a special machine for hot extrusion molding of plastic lenses with a value of only 5,000 yuan was made. Figure 6 (a) shows A schematic diagram of the structure is shown.

Fig.6 Hot compression molding device of making lens and photograph of lens sample

In order to make the molded product have a good surface, it is necessary to pre-dry the material before injection molding.

First, Topas COC needs to be vacuum-dried at 100°C for 6 hours in a drying oven to remove the dissolved oxygen in the pellets. If the material is injection-molded in the presence of dissolved oxygen, scorch may occur under high temperature and pressure for a long time, and the lens will be discolored and yellowed due to oxidation, or even carbonized and blackened.

Secondly, after the experiment, in order to make the lens separate from the mold smoothly and ensure the surface shape and smoothness of the lens surface, it is necessary to apply dimethyl silicone oil on the surface of the mold and the sleeve, and burn it at a high temperature of 220 ° C for half an hour.

After the mold is cooled, add 118g of material, put the mold after adding the material on the hydraulic pressure pump, the contact area between the hydraulic pump and the mold is 23.67cm², and the photo of the manufactured lens sample is shown in Figure 6 (b).

3.2 Influence of main parameters such as temperature and time on the lens surface

3.2.1 Influence of temperature on lens surface

Due to the special properties of the Topas COC material, the molding of the lenses is sensitive to temperature.

If the temperature is too low, the particles cannot be fully softened, which is not conducive to compression molding, and affects the smoothness and light transmittance of the lens surface. If the temperature is high, it is easy to cause material decomposition and change the structure and performance of Topas COC materials.

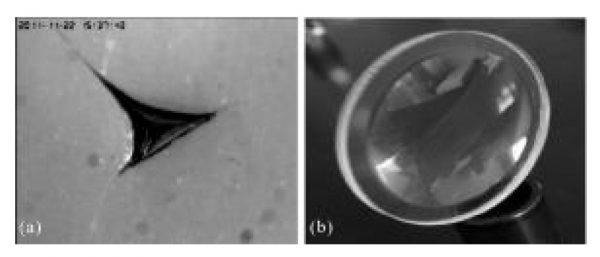

Since the digital display electric heating sleeve is sleeved on the outside of the mold sleeve, the temperature of the periphery of the mold rises faster than the center of the mold, and the particles in contact with the mold are softened first, which is easy to block the exhaust holes between the mold and the sleeve, so that the air between the particles does not flow. It can be discharged smoothly. Under high temperature and high pressure, the gas will accumulate on the upper surface of the lens to form a hollow, and there are a lot of air bubbles in the middle of the pellets, as shown in Figure 7.

Fig.7 Surface of lens

3.2.2 The effect of time on the lens surface

When the time is short, there are obvious traces between the particles inside the lens, and there are concave and convex spots of different sizes on the surface, as shown in Figure 8(a), which is an enlarged schematic diagram.

The reason for this result is that the particles are not sufficiently softened, and the polymer chains are not sufficiently fused. When the light passes through the lens, there is serious scattering and dispersion, which seriously affects the performance of the lens.

Therefore, a reasonable time can effectively avoid the above situation, improve the surface finish of the lens and reduce the traces between particles inside the lens, but the time should not be too long, otherwise the lens will slightly turn yellow, affecting the transparency of the lens.

Fig.8 Surface characteristics of lens

4 Analysis of lens focal length characteristics

Since there is no stable single-frequency terahertz light source in the laboratory, the author simulated and analyzed the focal length characteristics of the lens in the terahertz band (0.1~3THz) through Zemax software.

First, light with wavelengths of 150 μm, 300 μm, and 600 μm was selected as the analysis object. Through Zemax software, we simulated and analyzed the influence of various variables on the focal length of the lens at different wavelengths. The results are shown in Table 2.

where

d is the thickness of the lens;

r is the radius of curvature of the lens; and

n is the refractive index of the lens.

It can be concluded that:

- The thickness changes about ±0.5mm (6.669), and the focal length changes about ±0.1mm (0.1%), so the effect of thickness on the focal length of the lens can be ignored;

- The radius of curvature changes about ±2mm (1.98%), and the focal length changes about ±2mm (2%), so the radius of curvature will have a greater impact on the focal length of the lens;

- The refractive index of the material changes by ±0.01 (0.654%), and the focal length changes by ±1.9 mm (1.9%), so the refractive index will have a greater impact on the focal length of the lens; the change in temperature will have a certain impact on the refractive index of the material , so it can be speculated that the temperature will also affect the focal length of the lens; at the same time, the radius of curvature of the lens with a larger diameter is irregularly changed due to the shrinkage of the material, resulting in the surface of the lens is not an ideal spherical surface, which will also affect the focal length of the lens. It has a great influence on the imaging characteristics of the lens, so the effective aperture of the lens should not be too large.

Tab 2 Lens focal length of different parameters under different wavelengths (f/mm )

| λ/µm | d/mm | r/mm | n | ||||||||||||

| d0 | d' | d'' | r0 | r' | r'' | n0 | n' | n'' | |||||||

| 7.51 | 8 | 7 | 100.96 | 103 | 99 | 1.533 | 1.543 | 1.523 | |||||||

| 150 | 100 | 100.08 | 99.91 | 100 | 102 | 98.08 | 100 | 98.1 | 101.82 | ||||||

| 300 | 100 | 100.09 | 99.92 | 100 | 102 | 98.09 | 100 | 98.11 | 101.83 | ||||||

| 600 | 100 | 100.09 | 99.92 | 100 | 102 | 98.09 | 100 | 98.11 | 101.83 | ||||||

In the case where the lens thickness, curvature radius and refractive index are constant, the focal length of the lens at wavelengths of 150 μm, 300 μm and 600 μm are simulated in the terahertz band, and the focal lengths are all 100 mm, as shown in Table 2. The wavelength of the band is relatively long, which is caused by the small change in the refractive index of the Topas material in the terahertz band (0.1~2THz). Therefore, the dispersion of the Topas lens in the terahertz band (0.1~2 THz) is completely negligible, and the imaging quality is not affected by wavelength changes.

5 Conclusion

Topas COC has a small change in the refractive index in the terahertz band (0.1~2THz), and has a high transmittance in the visible light region and the terahertz band. It is one of the ideal terahertz materials.

Taking the commonly used terahertz lens with a focal length of 100mm as an example, the lens and the manufacturing mold are designed, and the terahertz lens is manufactured by a self-made thermocompression molding machine.

Studies have shown that the surface shape and precision of the mold will affect the surface finish of the lens and the radius of curvature of each point, and the molding shrinkage of the material will also affect the radius of curvature of the lens.

All of these will have a certain effect on the focal length of the lens, which in turn affects the light transmittance of the lens and its imaging characteristics.

Due to the limitation of the single-frequency terahertz light source, the relationship between the variables in the terahertz band and the focal length of the lens was simulated and analyzed. It is concluded that the curvature radius and refractive index of the lens are the main factors affecting the focal length characteristics.

The effect of wavelength and thickness on focal length is negligible, combined with the characteristics of the lens in the visible light band.

It is concluded that the Topas COC lens manufactured by the thermocompression molding method has a smooth surface, high precision, defect-free structure, and excellent performance in the terahertz band to meet the experimental needs. With the help of high-precision molds, large-scale manufacturing can be achieved.