How Sapphire is used in Optics?

Sapphire of different quality is employed in optical articles. The most recognized classification of sapphire optical quality is presented in the Appendix. Sapphire windows with diameters from several millimeters to several hundreds of millimeters are applied in various devices that work on the ground, under water, and in outer space in a wide range of pressures and temperatures – from cryogenic to high temperatures. An example design of a sealed-in window is presented in Fig. 1.31 . It is meant for use at temperatures starting from cryogenic and up to 720 К, with high pressures both internal and external.

Sapphire windows are applied in gas cryostats and helium microstats with D (12…25) × 2 mm, sealed in metallic flanges or gasketed in the sockets of devices.

Copper gaskets or indium wires provide a vacuum-tight seal to the cryostat.

Windows with a wedge of 1° and 3° are used in laser engineering as partially reflecting mirrors or prisms for laser beam control.

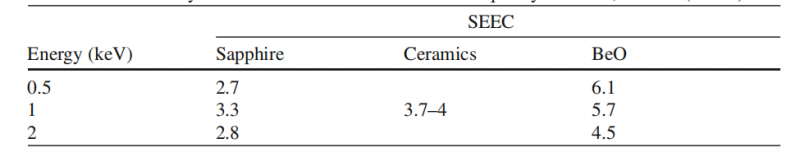

Sapphire energy withdrawal windows* can be used. One of the factors that limit the withdrawal of energy from devices is secondary electron resonance discharge in vacuum proportional to the secondary electron emission coefficient (Table below).

As seen from this table, sapphire compares favorably with other dielectrics in this characteristic.

Sapphire lenses and prisms are used under extreme conditions that glass analogs cannot withstand, or due to high refractive index characteristic of sapphire.

Sapphire light guides incorporated in continuous temperature control devices yield the most unbiased data concerning the state of a melt in melting, dispensing, and mixing furnaces. They can work in molten steels and alloys, or in strongly aggressive melts. Sapphire is the only existing optical material that preserves its optical properties and serviceability in cast iron and steel melts. The light guide is fed through the furnace lining in such a way that one of its ends is put into the melt and the other end is located outside the lining. The intensity of the light guide glow is proportional to the temperature of the melt. By means of a pyrometric converter the thermal radiation is transformed into a signal for the automated temperature control system.

To raise the strength of the sapphire rod, it is fixed into a ceramic

tube using a high-temperature ceramic compound, and the resulting bar is then installed into the lining . The light guides incorporated into the bar work during the entire technological cycle until the lining is replaced. In melted gold, sapphire light guides with a diameter of 4 mm withstand heating up to 2,070 K and subsequent cooling at a rate of 2 deg/s.

Naturally, the lowest losses by light absorption and scattering are characteristic of leucosapphire. However, the flow of light from metallurgical furnaces is so intense that there is no need to “economize” it. The use of leucosapphire light guides with ruby tips introduced into the melt allows increased measurement accuracy: the transmitted light intensity remains proportional to the temperature, but is clarified by the additional measurement of chromium luminescence intensity.

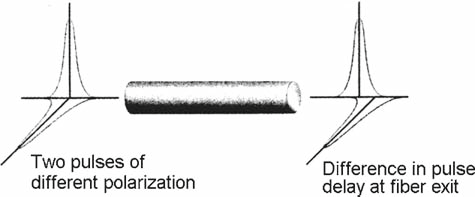

Sapphire optical fibers are also classified as light guides. In fiber grown along the C axis the propagation of light does not depend on the polarization. However, in real fibers a polarization anisotropy caused by circular symmetry breaking or local stresses connected with bending, compression, and twisting arises. Induced birefringence gives rise to the appearance of a difference between the phase and

group rates of light-wave propagation in fiber polarized along the two axes. Such a difference leads to lagging of the pulse polarized along the “slow” axis of birefringence, as well as to the appearance of a difference between the phases of two polarized components.

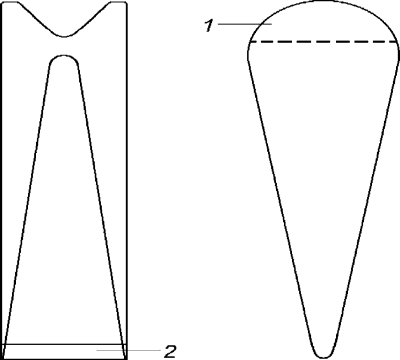

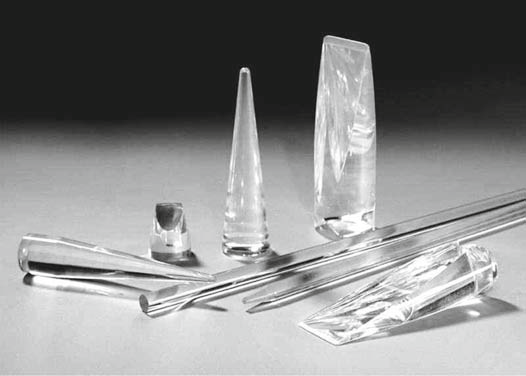

Focusing cones (focones) also belong to light guide facilities. By means of sapphire focones the emission of high-power xenon lamps is transformed into a point or linear source (“light knife”). For the latter transformation the shape of the input face is calculated (Figure below), allowing redistribution of incident light flux in the required way.

Light guides and focones of different designs are shown in Figure below.

In some cases it is easier to carry out temperature measurements by means of traditional thermocouples, but in aggressive medium these quickly break down.

Thermocouple casings made of sapphire in the form of tubes with hermetically sealed bottoms provide reliable protection of metallic thermocouples from aggressive media.

Sapphire meniscuses (domes) shaped as hemispheres are used for making the heads of IR-radiation guided missiles. Here, sapphire is employed due to the combination of its sufficient transmission in the region of 3–5 m m and its mechanical strength. The temperature of the working article, and consequently the value of transmission and guiding accuracy, are defined by the outer surface roughness.

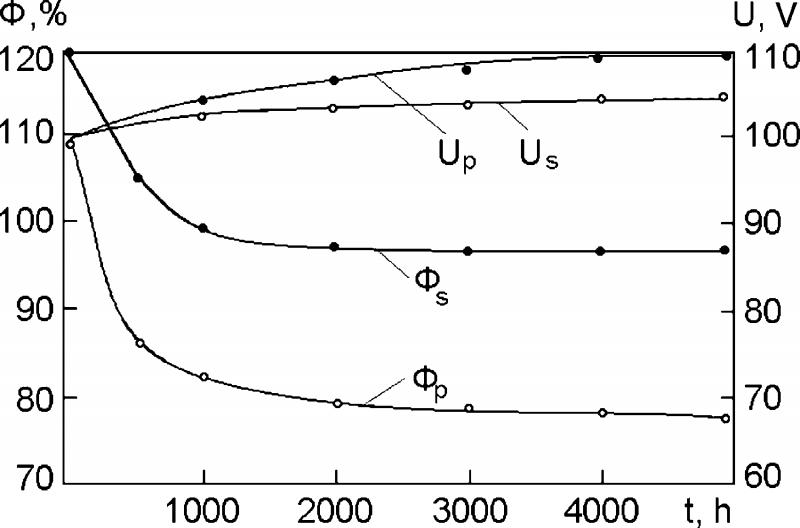

Sapphire shells for sodium high-pressure lamps are competitive with polycrystalline shells. The grain boundaries in polycrystalline shells promote the diffusion of sodium (at working temperatures the coefficient of diffusion along the grain boundaries exceeds the bulk coefficient of diffusion by approximately three orders of magnitude), thus shortening the service life of the polycrystalline articles.

Although polycrystalline shells are cheaper, sapphire shells possess higher transparency, consume less energy, have a longer service life, and maintain a higher stability of light flux.

The lamps with quartz shells used for pumping solid-state laser elements also have a number of drawbacks. Sapphire shells possess higher thermal conductivity and strength; sapphire has an immeasurably higher resistance to alkali metals. The lamps with sapphire shells withstand higher temperatures.

With other conditions being equal, the value of mechanical strength and ultimate electrical loads on the shell depend on the quantity of blocks in the tube. Shells without blocks withstand loads exceeding 390 W/cm 2, while the ultimate power decreases to 150 W/cm 2 for those containing 5 blocks and 60 W/cm 2 for those with 7–15 blocks.

Sapphire shells for lamps, absorption cells, and filters of atomic (rubidium) frequency standards raise the characteristics of the devices: they diminish the relative frequency change corresponding with the time of work and atmospheric pressure, decrease power consumption, and increase the mean time between failure of devices. Due to their high thermal conductivity, sapphire shells allow withdrawal of heat from laser elements made of materials with low thermal conductivity.

Transparent sapphire shells are able to protect Mo-heaters from oxidation or aggressive media.