Optics Packaging, Shipping and Storage

Packaging, storage and shipping (delivery) of the goods to its destination is the concern of the customer and the producer of the goods to be shipped.

The customer, if he is the designer of the item and the author of the drawing or requirement can write for example the following: “Each item shall be individually wrapped with an “optical components soft wrapping tissue”.

The wrapped item shall be packed in a stiff package for overseas shipment in packaging that will prevent any damage of the items during handling of the package and transportation. It is allowed to pack several components (of the same type) in one stiff package” or in some cases to define a special packaging type followed by drawing or packaging specification which are a part of the purchasing order.

The supplier or the producer of the item, even if there is a missing packaging requirement for customer’s design or for shelf items, has an obligation to pack and deliver the items in such way that the items will arrive in safe condition to the customer.

Packaging

There are different kinds of packaging that suit and complete packing optical elements:

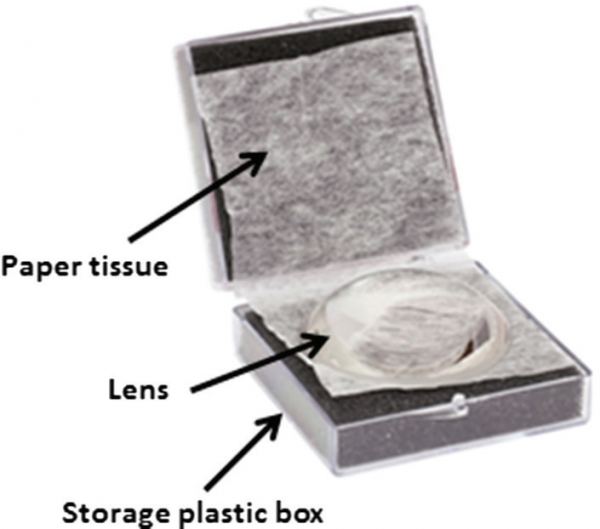

- Most optical cleaning tissues can be used to wrap the optical element for storage inside a specially designed optics storage box.

- Padded lens packaging.

- Packing envelopes (nylon and nylon covered with paper).

- Polystyrene chips.

- Cartoon boxes.

- Bubble nylon rolls are very useful for covering big items or for filling the empty area in cartons and plastic or wooden boxes to prevent packed items from moving. Bubble nylon can replace polystyrene chips for this purpose.

Storage

Typically, any sort of packaged optics should be kept in a low-humidity, low contaminant, and temperature-controlled environment to prevent any possible damage to the optical items and their coatings. Silica gel should sometimes be added to the package to keep the relative humidity as low as possible (silica gel absorbs the humidity and keeps the area dry). Silica gel is poisonous (see the MSDS), comes in different colors and packages and changes color when it absorbs humidity (e.g., orange to green, orange to colorless, etc.).

Shipping

Shipping or delivering stored items to their destination (external or internal customer) is not the last step in the production chain, but it is the last one that connects the producer to the station where the items are assembled. Correct handling of the packaging, storage, and shipping steps assures that the items reach the next station in the production line in the same condition as at the packaging stage, i.e., without any damage to the item, its coating, and its bonding (if any)