A design example of 885nm Nd:YAG Laser

In laser design, how to reduce the influence of thermal effect on laser output has always been a technical difficulty in laser design. From lamp pumping to the now widely used 808nm LD pumping, although the laser performance has been greatly improved, the thermal effect also seriously restricts the laser output performance. To further reduce the thermal effect, an effective and low-cost way is to reduce the Stokes frequency. Shift, direct pumping technology can achieve this purpose.

Theoretical Analysis

Compared with the traditional 808nm pumping technology, direct pumping means that ions are directly excited from the fundamental energy level of the material to the upper laser energy level during optical pumping, which can effectively reduce the Stokes frequency shift and quantum defect. In 1968, ROSS was the first to demonstrate direct pumping of Nd:YAG crystals. Subsequently, there have been reports of direct pumping using Ti:sapphire as the pumping source. With the advancement of diode manufacturing technology, higher-power diodes that better match Nd+3 host crystals have led to the development of direct pumping technology.

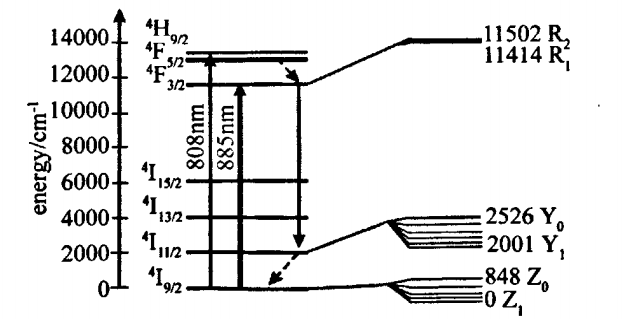

The direct pumping technique was initially used at 869 nm, and it was subsequently validated at 885 nm. The figure below shows the energy level diagrams when pumping at 808nm and 885nm. For traditional 808nm LD pumping, Nd:YAG ions transition from the base level to 4F5/2, and then go through a non-radiative transition to the upper laser level 4F3/2, This process is also a heat-generating process. In addition, using 808nm LD to pump Nd:YAG, when the output is 1064nm, the quantum loss is 24%. If 885nm LD is used for direct pumping, the quantum loss will be reduced to 17%, which directly leads to a nearly 30% reduction in heat accumulation.

Experiment and its results

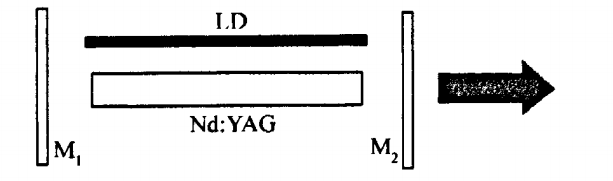

In the experiment, the flat cavity structure was adopted, the side pumping mode of the diode array was adopted, the central wavelength of the LD was 885 nm, and the overall temperature was controlled by a thermoelectric cooler. The whole experimental setup is shown in Fig.

The crystal size is 5.5mm×55mm, and both ends of the crystal are coated with 1064nm antireflection film. M1 is a total reflection mirror, coated with 1064nm, 885nm total reflection film, and M2 is an output mirror. A self-made high-stability LD driver is used to provide a high-stability working current for the LD.

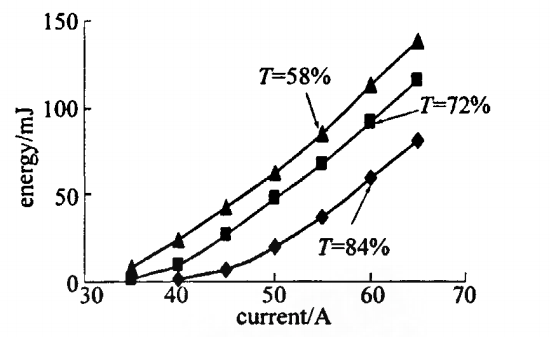

A static output test was carried out using an 885nm diode array pumped Nd:YAG crystal. Three kinds of output mirrors with transmittance T of 84%, 74% and 58% were selected for comparison experiments, and the curves are shown in the figure.

When the output mirror with a transmittance of 58% is used, the output advantage is obvious, the threshold current is small, and the output energy obtained is also large. The linearity of the entire output curve is very good. When the maximum input current is reached, the output energy does not appear saturated or attenuated. If the input power is increased, the output can be increased. In the experiment, the static output of the maximum single pulse is 138mJ, and the light-to-light conversion efficiency is 12%.

An important reason for the low conversion efficiency is that the absorption efficiency of Nd:YAG crystal for 885nm wavelength is too low. Under comprehensive consideration, its effective absorption coefficient is only 1/3 of that of 808nm pumping. In the test, the transmittance is not further optimized, and the loss in the cavity is too large when the absorption coefficient is obviously small. On the other hand, the coupling of the pump light is not optimized, which is also a factor in the low absorption. If the above improvements are made, the output effect should be better.

In conclusion

The all-laser pumped Nd:YAG with 885nm LD is experimentally verified. By comparing the output mirrors with different transmittances, a relatively better output result was obtained when the transmittance of 58% was selected. The maximum energy of static output was 138mJ, and the light-to-light conversion efficiency was 12%. The output results in this paper are not ideal, especially the light-to-optical conversion efficiency is low. If the entire laser is optimized, the overall performance will be improved.