Choosing the Right Crystal Size and Cut for Your Laser

Angle adjustment

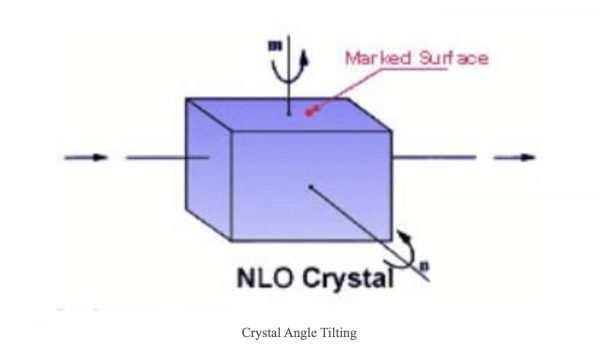

In order to obtain the maximum conversion efficiency, angle adjustment is the most common method to achieve the phase matching direction. There are two axes to adjust the crystal angle as shown in the figure.

NLO crystals are mainly cut in the direction of the common crystal plane, so adjusting the n-axis does not help to improve the conversion efficiency. However, when the m-axis is moved, usually the dotted plane, there are obviously different effects. Customers must pay extra attention when rotate the m-axis.

Optimum crystal size and cut

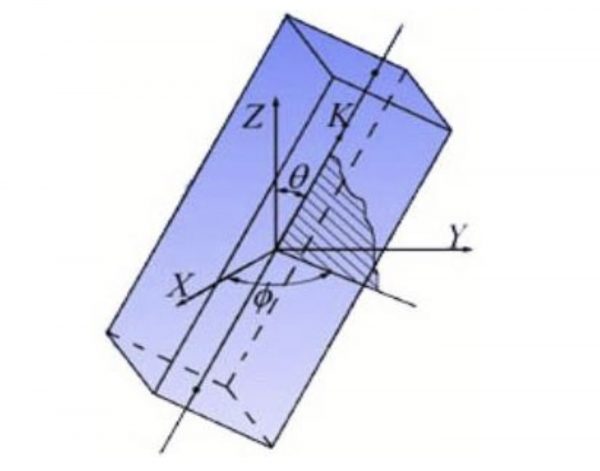

When choosing an NLO crystal, please try to provide the cutting angle and size of the crystal. Different angle orientations will produce different nonlinear effects. For example, when the class I frequency doubling is 1064nm, the cutting angle of BBO is θ=22.8 degrees and Φ= 0 degree.

Remarks: θ is the polar angle of the optical axis and the light passing direction. And Φ is the projected azimuth angle with the X axis and the light passing direction on the XY plane.

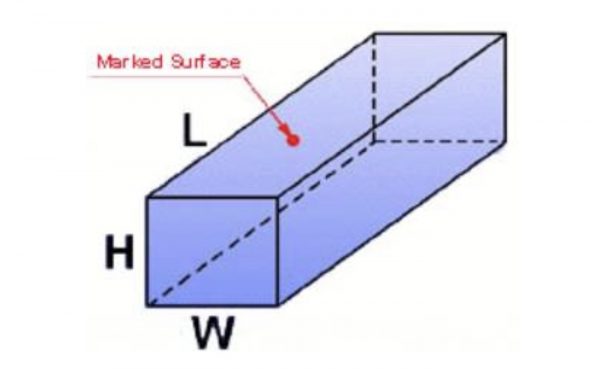

For crystal size, it is generally divided into width (W), height (H) and length (L), commonly written as W×H×Lmm3. Please design the crystal size carefully because the price is proportional to the volume, and the crystal length is the key to affecting the conversion efficiency directly. As for the crystal height (H), the laser beam diameter is the main consideration. The ideal height is slightly larger than the beam diameter, such as about 1 to 2mm long.

When designing the width of ideal crystal, the beam width and the tunable wavelength range are the main considerations. If it is a unidirectional NLO process, such as frequency doubling 532nm, we will choose W=H. But for a tunable wide wavelength NLO process, in using BBO as an example of frequency doubling in dye lasers from 440nm to 660nm, the crystal needs to be adjusted from θ=36 degrees to θ=66.6 degrees. The width (W) can be calculated by the formula: H+2tan((66.6-36)/2)×L , If the crystal height (H) is 4mm and the length (L) is 7mm, W is about 8mm.

Each NLO crystal has its standard as the length of the pulse width longer than nanoseconds (ns) for laser frequency doubling. For example, the standard lengths of BBO and KTP are 7mm and 5mm. However, in OPO and OPA, the required length of BBO is is >12mm, while SHG and THG in ultrafast pulsed lasers require the use of thin crystals less than 1mm.