Low Order Waveplate

High Damage Threshold

Better Temperature Bandwidth

Low Cost

Thickness: 0.2-0.5 mm

Material:

Quartz

Retardation Tolerance:

<λ/300

Surface Quality:

20/10

C.A:

>90%

Damage Threshold:

>10J/cm², 20ns, 20Hz at 1064nm

Wavelength:

200~2300nm

Parallelism:

<1”

Wavefront Distortion:

λ/8 @ 632.8nm

Coating:

AR/AR@wavelength

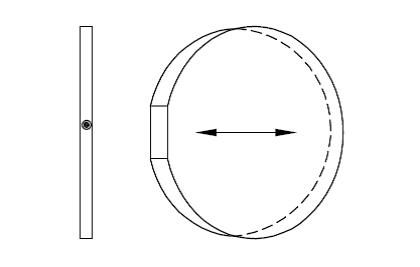

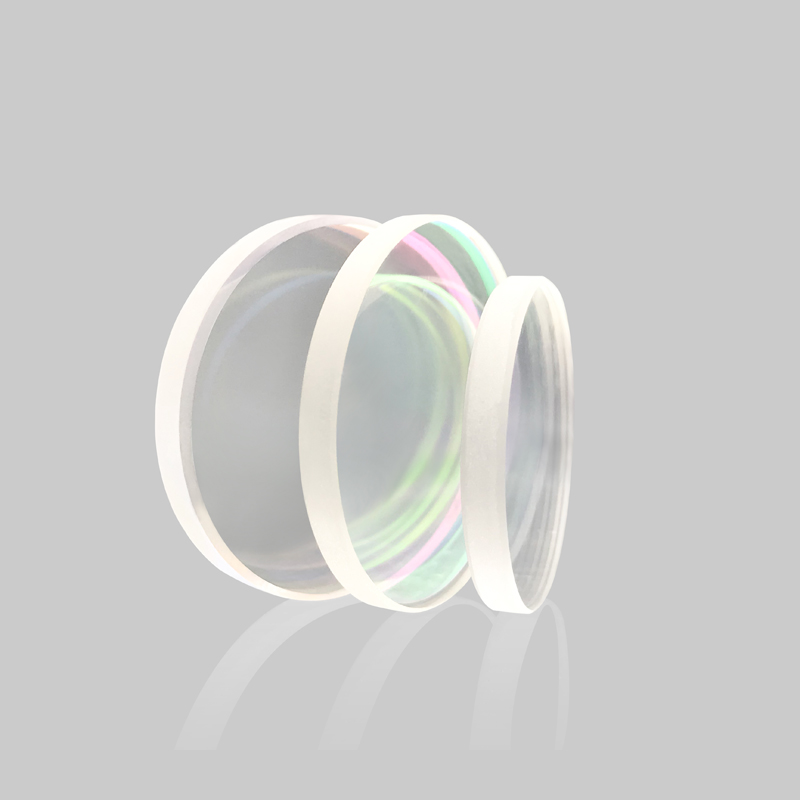

Low Order Waveplate can yield λ/4 or λ/2 retardation by selecting some specified thickness. And it is much better than the multi-order waveplates because of its thinner thickness, better temperature, wave length and incidence angle, bandwidth and high damage threshold. These properties make it widely used for high and low power laser application. Thickness: 0.2-0.5 mm

| wdt_ID | Attributes | Value |

|---|---|---|

| 76 | Material: | Quartz |

| 77 | Wavelength: | 200~2300nm |

| 78 | Diameter Tolerance: | +0.0 / -0.1mm |

| 88 | Surface Quality: | 20/10 |

| 89 | Parallelism: | <1'' |

| 90 | Retardation Tolerance: | <λ/300 |

| 91 | C.A: | >90% |

| 96 | Wavefront Distortion: | λ/8 @ 632.8nm |

| 101 | Damage Threshold: | >10J/ cm², 20ns, 20Hz at 1064nm |

| 102 | Coating: | AR/AR@wavelength |

| 103 | Mount: | Black Anodized Aluminium |

The most common types of waveplates are quarter-wave plates (λ/4 plates) and half-wave plates (λ/2 plates), where the difference of phase delays between the two linear polarization directions is π/2 or π, respectively, corresponding to propagation phase shifts over a distance of λ / 4 or λ / 2, respectively.

Some important cases are:

-

When a light beam is linearly polarized, and the polarization direction is along one of the axes of the waveplate, the polarization remains unchanged.

-

When the incident polarization does not coincide with one of the axes, and the plate is a half-wave plate, then the polarization stays linear, but the polarization direction is rotated. For example, for an angle of 45° to the axes, the polarization direction is rotated by 90°.

-

When the incident polarization is at an angle of 45° to the axes, a quarter-wave plate generates a state of circular polarization. (Other input polarizations lead to elliptical polarization states.) Conversely, circularly polarized light is converted into linearly polarized light.

Within a laser resonator, two quarter-wave plates around the gain medium are sometimes used for obtaining single-frequency operation (→ twisted-mode technique). Inserting a half-wave plate between a laser crystal and a resonator end mirror can help to reduce depolarization loss. The combination of a half-wave plate and a polarizer allows one to realize an output coupler with adjustable transmission.

Many waveplates are made of crystalline quartz (SiO2), as this optical material exhibits a wide wavelength range with very high transparency, and can be prepared with high optical quality. Other possible materials (to be used e.g. in other wavelength regions) are calcite (CaCO3), magnesium fluoride (MgF2), sapphire (Al2O3), mica (a silicate material), and some birefringent polymers.

Standard Wavelength:

355nm, 532nm, 632.8nm, 780nm, 808nm, 850nm, 980nm, 1064nm, 1310nm, 1480nm, 1550nm

| 1/4 (Quarter Waveplate) | 1/2(Half Waveplate) | wdt_ID | Diameter(mm) | values |

|---|---|---|---|---|

| WPL5410 | WPL5210 | 27 | 10 | WPS7410 |

| WPL5412 | WPL5212 | 50 | 12.7 | WPS7412 |

| WPL5415 | WPL5215 | 68 | 15 | WPS7415 |

| WPL5420 | WPL5220 | 69 | 20 | WPS7420 |

| WPL5425 | WPL5225 | 70 | 25.4 | WPS7425 |

| 71 |