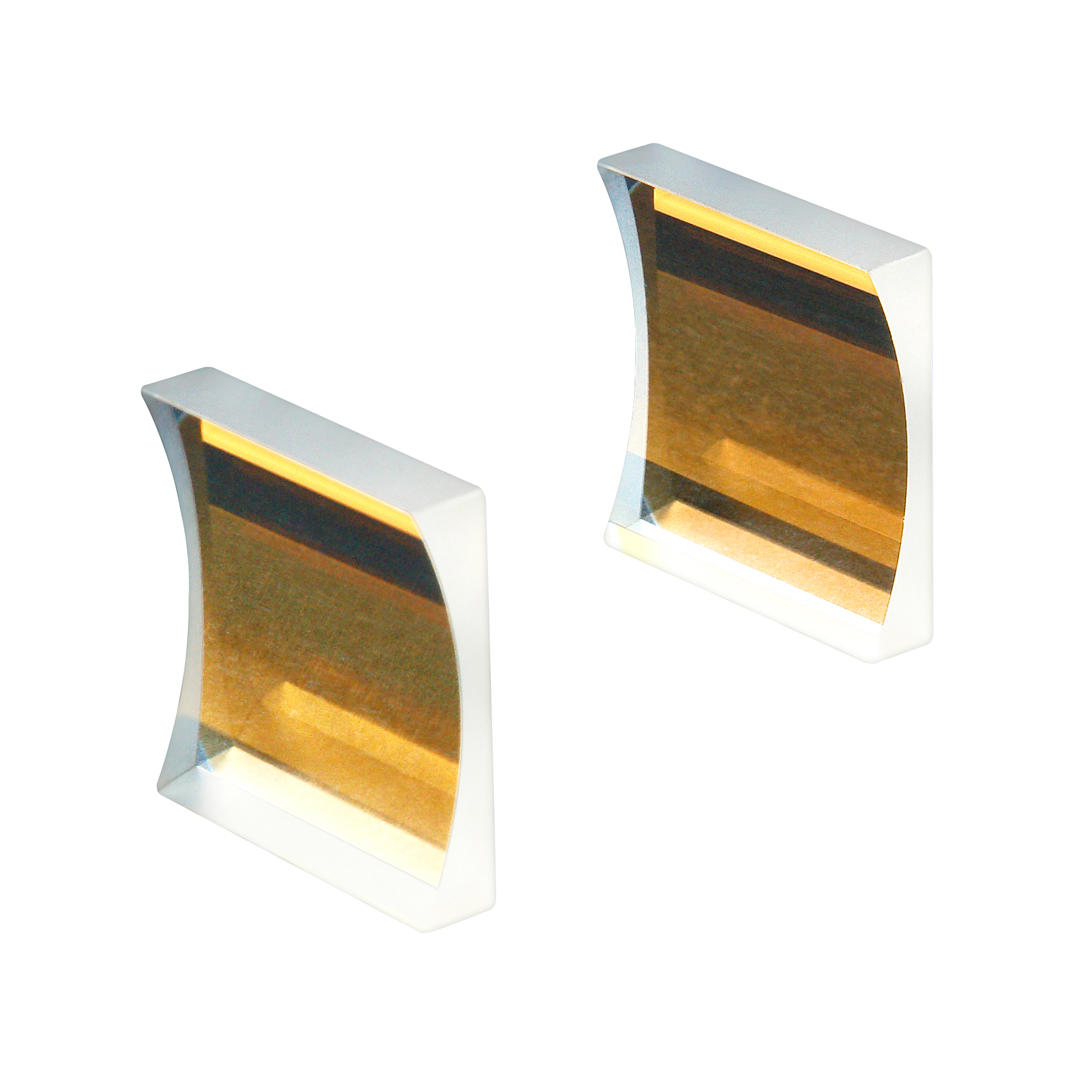

Concave Cylindrical Mirrors

Substrate Material:

N-BK7, UV Fused Silica

Surface Flatness (Typ.):

1 λ@633nm

Coating Available:

1- UV Enhanced Aluminum,

2- Protected Aluminum,

3- Protected Silver,

3- Protected Gold

Surface Quality (Typ.):

60/40 to 40/20

Clear Aperture:

≥80%

Typical Price Range (For sample) : 70~100$

What is a Concave Cylindrical Mirror

A Concave Cylindrical mirror is an optical element that has a cylindrically shaped surface. It differs from a spherical mirror by focusing a beam to a focal line rather than a focal point1. Concave Cylindrical mirrors are used for applications such as laser scanners, laser diode systems, spectrophotometers, projectors, optical data storage and retrieval systems. Concave Cylindrical mirrors can be made of different materials and coatings depending on the wavelength range and reflectivity required.

Common Specification and Products

| wdt_ID | Attributes | Values |

|---|---|---|

| 1 | Material | N-BK7 |

| 17 | Size&Tolerance | W(+0/-0.2)*H(+0/-0.2)*L(±0.1)mm |

| 18 | Surface quality | 60/40~40/20 |

| 21 | Flatness | 1λ@633nm |

| 25 | Centering | ≤3 arc min |

| 54 | Bevel | <0.2mmx45° |

| 57 | CA | ≥80% |

| 58 | Chips | <0.2mm |

| 59 | Coatings | 1--- UV Enhanced Aluminum 2--- Protected Aluminum 3--- Protected Silver 3--- Protected Gold |

| wdt_ID | P/N | Material | Dia/Tc (mm) | Focal Length(mm) | Coating |

|---|---|---|---|---|---|

| 539 | CCM112525 | N-BK7 | Φ12.5x3.0 | 25 | 1/2/3/4 |

| 540 | CM1125100 | N-BK7 | Φ12.5x3.0 | 100 | 1/2/3/4 |

| 541 | CM1125200 | N-BK7 | Φ12.5x3.0 | 200 | 1/2/3/4 |

| 542 | CM1125300 | N-BK7 | Φ12.5x3.0 | 300 | 1/2/3/4 |

| 546 | CCM125100 | N-BK7 | Φ25.0x6.0 | 100 | 1/2/3/4 |

| 547 | CCM125200 | N-BK7 | Φ25.0x6.0 | 200 | 1/2/3/4 |

| 548 | CCM125300 | N-BK7 | Φ25.0x6.0 | 300 | 1/2/3/4 |

| 549 | CCM125400 | N-BK7 | Φ25.0x6.0 | 400 | 1/2/3/4 |

| 550 | CCM125600 | N-BK7 | Φ25.0x6.0 | 600 | 1/2/3/4 |

| 551 | CCM125800 | N-BK7 | Φ25.0x6.0 | 800 | 1/2/3/4 |

| 552 | CCM1251000 | N-BK7 | Φ25.0x6.0 | 1000 | 1/2/3/4 |

| 569 | CCMS112550 | N-BK7 | 12.5x12.5x3.0 | 50 | 1/2/3/4 |

| 570 | CCMS1125100 | N-BK7 | 12.5x12.5x3.0 | 100 | 1/2/3/4 |

| 571 | CCMS1125200 | N-BK7 | 12.5x12.5x3.0 | 200 | 1/2/3/4 |

| 572 | CCMS1125300 | N-BK7 | 12.5x12.5x3.0 | 300 | 1/2/3/4 |

| 573 | CCMS125100 | N-BK7 | 25.0x25.0x6.0 | 100 | 1/2/3/4 |

| 574 | CCMS125200 | N-BK7 | 25.0x25.0x6.0 | 200 | 1/2/3/4 |

| 575 | CCMS125300 | N-BK7 | 25.0x25.0x6.0 | 300 | 1/2/3/4 |

| 576 | CCMS125400 | N-BK7 | 25.0x25.0x6.0 | 400 | 1/2/3/4 |

| 577 | CCMS125600 | N-BK7 | 25.0x25.0x6.0 | 600 | 1/2/3/4 |

| 578 | CCMS125800 | N-BK7 | 25.0x25.0x6.0 | 800 | 1/2/3/4 |

| 583 | CCMS1251000 | N-BK7 | 25.0x25.0x6.0 | 1000 | 1/2/3/4 |

Applications of Concave Cylindrical Mirrors

Cylindrical mirrors are used in some applications. Here are some examples:

- Laser scanners: Cylindrical mirrors can be used to scan a laser beam across a surface or a detector. For example, a barcode scanner uses a cylindrical mirror to reflect a laser beam onto a barcode and then collect the reflected light back to a sensor. Cylindrical mirrors are preferred over spherical mirrors for this application because they can focus the beam to a line without introducing spherical aberration or chromatic aberration.

- Laser diode systems: Cylindrical mirrors can be used to collimate or focus the output of a laser diode, which typically has an elliptical beam shape. By using two cylindrical mirrors with orthogonal orientations, the beam can be shaped into a circular or square profile1. Cylindrical mirrors are preferred over cylindrical lenses for this application because they do not introduce dispersion or absorption of the laser light.

- Spectrophotometers: Cylindrical mirrors can be used to direct light from a source to a sample and then to a detector in a spectrophotometer, which measures the intensity of light at different wavelengths. By using cylindrical mirrors, the optical path can be shortened and simplified, reducing the loss of light and improving the accuracy of the measurement1. Cylindrical mirrors are preferred over spherical mirrors for this application because they can maintain the collimation of the light without introducing spherical aberration or chromatic aberration.