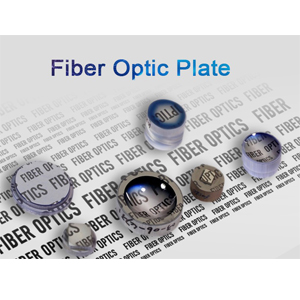

Fiber Optic Plate

Fiber Pitch:

2.5um / 3um /4um /6um /

50um / 70um / 80um / 100um

or customized

Maximum Format:

Φ200mm

Core/Clad Ratio:

65/35~80/20 or customized

Numerical Aperture:

1.0

Thickness:

From 0.3mm and up

EMA Absorber:

Interstitial / Annular / Without

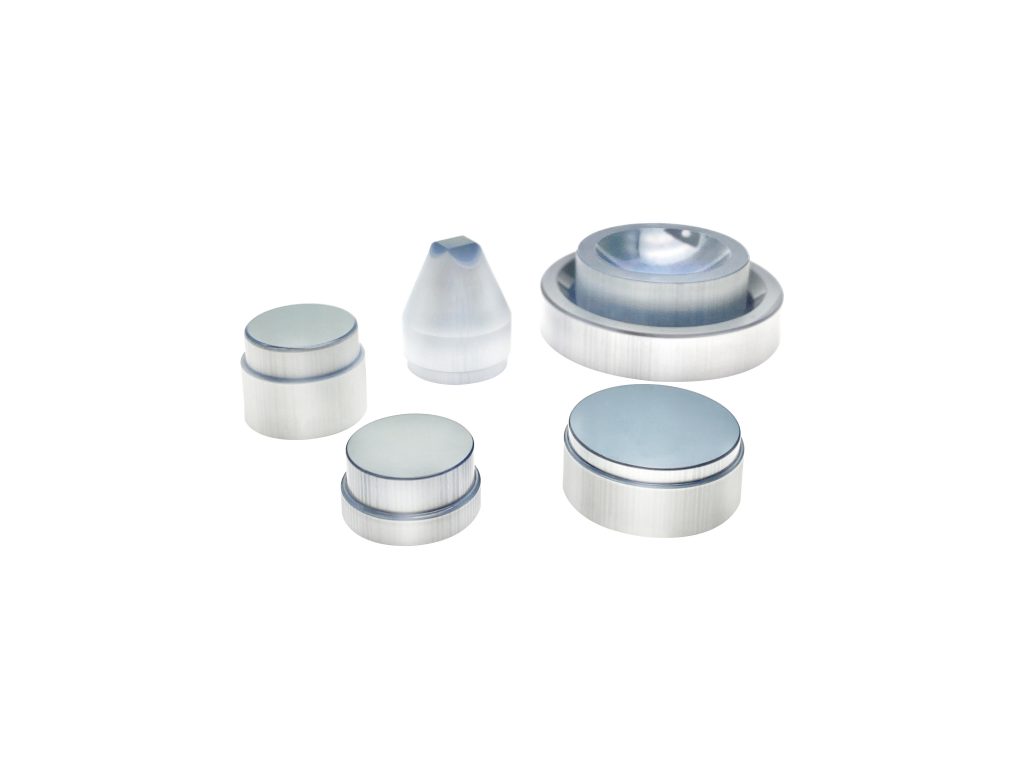

Fiber Optic Plate can act as a relay component for conveying image from one side to another side. Due to no requirement on focus distance, it can be used in many compact optical design.

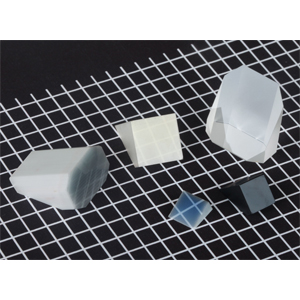

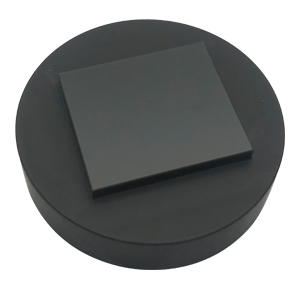

And the shape could be very flexible, Round, Square, Concave, Convex or customized.

Features:

- A “Zero-Thickness “Optical Window for image transfer.

- Numerical aperture ranging from 0.09 – 1.0. Useful for angular light control.

- Reduce color shift and Non-uniform brightness. Enhance Contrast.

- Blocking Xray from damaging CMOS/CCD (Xray Shielding Type FOP)

Application:

- Dental Xray

- Scientific Camera

- Fingerprint Sensing

- Angular Filter

wdt_ID Attribute Value

8

Single Fiber diameter

2.5um / 3um /4um /6um

/ 50um / 70um / 80um / 100um

or customized

9

Coefficient expansion at (20~300℃):

60~90 x10⁻⁷/℃

10

Vacuum tightness:

< 10⁻¹²Pa.m³/s

11

Numerical aperture

1.0

12

Collimating transmittance

>70%

13

Diffuse light transmittance

>65%

14

Shear Distortion

<30μm

15

Gross Distortion

<40μm

16

Frame run-out

≤100μm

17

EMA Absorber

Interstitial / Annular / Without

18

Core/Clad Ratio

From 65/35~80/20 or customized

19

Maximum Format

Φ200mm

20

Thickness

from 0.3mm and up

Following explanation to the terms that you should know about Fiber Optic Plates.

1.Fiber Diameter (Pitch)

Diameter of a fiber strand / Distance between fiber centering

2.Numerical Aperture

Capability of light gathering of fiber optic components.

3.Resolution

The measure of how closely lines can be resolved in one milimeter

4.EMA

Extra Mural Absorption(EMA) are small black fibers that inserted between 2 fiber strands. Which will absorb stray light between fibers.

5.Core

The transmitting part of the fiber optic wave guide. (Core usually has higher refraction index than cladding)

6.Cladding

The cover outside core, cladding has a lower index of refraction than core.

7.Packing Fraction

Ratio of Core area to Total area, this will shows the light transmission efficiency of the component.

9.Transmission

Comparison between Output light intensity and Input Light Intensity

10.Optical Crosstalk

The light escape from one fiber strand and get into another fiber.

11.Blemish

Blemishes are the area where transmission is reduced. Blemish is caused by contaminants along in the fibers.

12.Chickenwire

Chicken wire appear likes a black line on the components. The result of chicken wire is due to mal-control of temperature or pressure during the procedure.

13.Coefficient Thermal Expansion

CTE defined as the changing of dimension when the fiber components exposed to changing temperature environment

14.Shear Distortion

Shear distortion is cause by the misalignment of fiber during fusion process.

|

|

15.Gross Distortion

Gross Distortion is cause by in-proper Temperature/Pressure and Material input procedure.

|

|

High NA Fiber Optic Plate

wdt_ID Model Shape Fiber Diameter (μm) Numerical Aperture Dimension

13

FOP-R101

Round

6

1

dia.10mm x 1mm(t)

14

FOP-R102

Round

6

1

dia.10mm x 2mm(t)

15

FOP-R202

Round

6

1

dia.20mm x 2mm(t)

16

FOP-R302

Round

6

1

dia.30mm x 2mm(t)

17

FOP-S552

Square

6

1

5mm x 5mm x 2mm(t)

18

FOP-S15145

Square

6

1

15mm x 14mm x 5mm(t)

19

FOP-R233

Round

3

1

dia 23mm x 3mm(t)

20

FOP-S25351

Square

4

1

25mm x 32mm x 1mm(t)

21

FOP-S49482

Square

6

1

49mm x 48mm x 2mm(t)

22

FOP-S25505

Square

6

1

50mm x 25mm x 5mm(t)

23

FOP-S75252

Square

6

1

75mm x 25mm x 2mm(t)

| wdt_ID | Model | Shape | Fiber Diameter (μm) | Numerical Aperture | Dimension |

|---|---|---|---|---|---|

| 13 | FOP-R101 | Round | 6 | 1 | dia.10mm x 1mm(t) |

| 14 | FOP-R102 | Round | 6 | 1 | dia.10mm x 2mm(t) |

| 15 | FOP-R202 | Round | 6 | 1 | dia.20mm x 2mm(t) |

| 16 | FOP-R302 | Round | 6 | 1 | dia.30mm x 2mm(t) |

| 17 | FOP-S552 | Square | 6 | 1 | 5mm x 5mm x 2mm(t) |

| 18 | FOP-S15145 | Square | 6 | 1 | 15mm x 14mm x 5mm(t) |

| 19 | FOP-R233 | Round | 3 | 1 | dia 23mm x 3mm(t) |

| 20 | FOP-S25351 | Square | 4 | 1 | 25mm x 32mm x 1mm(t) |

| 21 | FOP-S49482 | Square | 6 | 1 | 49mm x 48mm x 2mm(t) |

| 22 | FOP-S25505 | Square | 6 | 1 | 50mm x 25mm x 5mm(t) |

| 23 | FOP-S75252 | Square | 6 | 1 | 75mm x 25mm x 2mm(t) |